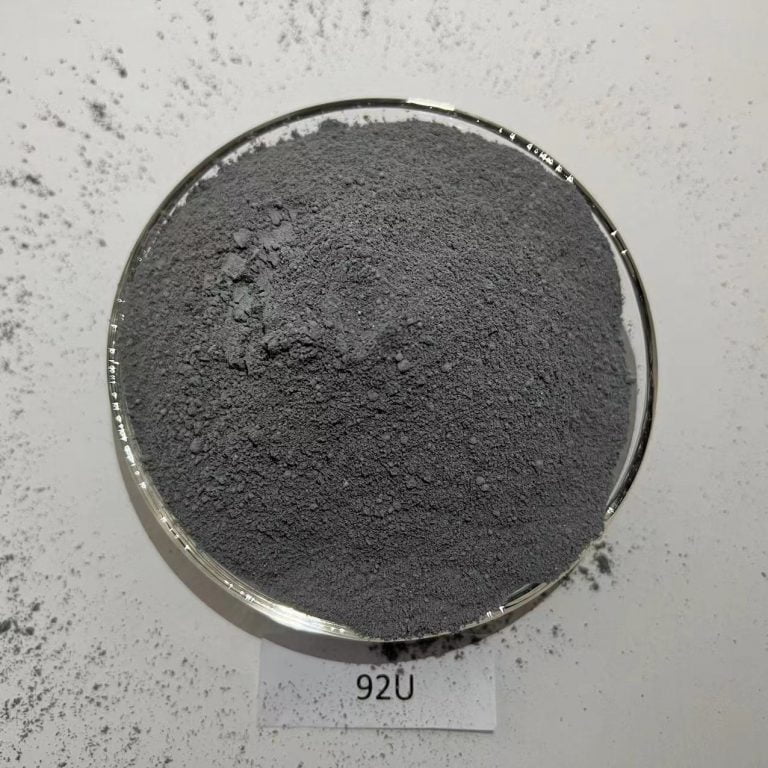

Micro silica fume powder is widely used in cement or concrete to improve the performance of cement or concrete because of its light quality, small particle size, large specific surface area and high volcanic ash activity. So what is the specific role of microsilica fume powder in concrete?

Adding the right amount of micro silica fume powder with proper particle size distribution in the concrete can play the following roles:

Enhancing Effect

Silica fume, as one of the active mineral admixtures applied in concrete, can improve the composition of cement stone cementitious material after admixture, especially can reduce and eliminate free lime. Because the SiO2 in the active mineral can produce volcanic ash reaction with free lime and high alkaline hydrated calcium silicate to produce lower alkaline hydrated calcium silicate with higher strength and better stability, the quantity of cementitious material is greatly increased and the interface structure between cement stone and aggregate is greatly improved. As a result, the strength of the concrete is increased significantly. This is the enhancement effect of silica fume on concrete.

Filling Effect

In the concrete mixed with an appropriate amount of ultrafine mineral admixture —-Silica fume (Average particle size 0.10-0.26um), because its average particle size is another order of magnitude smaller than that of fly ash and slag, silica fume can further fill in the voids between fly ash and slag particles, so that the denseness of the particles of the cementitious material is further improved and the strength is further increased. In addition, the filling effect improves the denseness of concrete, and therefore also improves the durability of concrete.

Plasticizing Effect

Under the synergistic effect of high efficiency water reducing agent, in the mixing process, the surface of very small spherical silica fume powder particles is covered with a layer of surface active material, and cement particles and other mineral admixture particles, so that the electrostatic repulsion between the particles, as the spherical silica fume particles are much smaller than cement particles, they play a “ball” between the cement particles As the spherical silica fume particles are much smaller than the cement particles, they play a “ball” role between the cement particles, which increases the fluidity of the cement slurry, thus making pumping and filling easier, so the enhancement effect can be effectively reflected.

Improvement of Concrete Durability

Active silica fume into the concrete hydrate to form a large number of low-alkaline hydrated calcium silicate gel, they can absorb and fix a large number of Na +, K + ions, so that the effective alkali content of the concrete pore solution is greatly reduced, and therefore, greatly reduce the harmful effects of alkali aggregate reaction. Moreover, the silica fume can also fill in the voids between cement particles and interfaces, so that the permeability of concrete is greatly improved, so that water and erosion medium is difficult to enter the interior of the concrete, so the durability of concrete is greatly improved.

Discover the Remarkable Characteristics of Silica Fume and Elevate Your Projects with Unparalleled Strength and Durability. For inquiries and to harness the power of Silica Fume, reach out to us at Ewende. Your path to construction excellence starts here!